20% off for big promotion

1. Features

1) Type: iPhone series half screen transparent tempered film;

2) Product technology: tempering;

3) Material: South glass high aluminum + 0.33mm AB adhesive.

4) Pencil hardness: 9H, can effectively resist scratching.

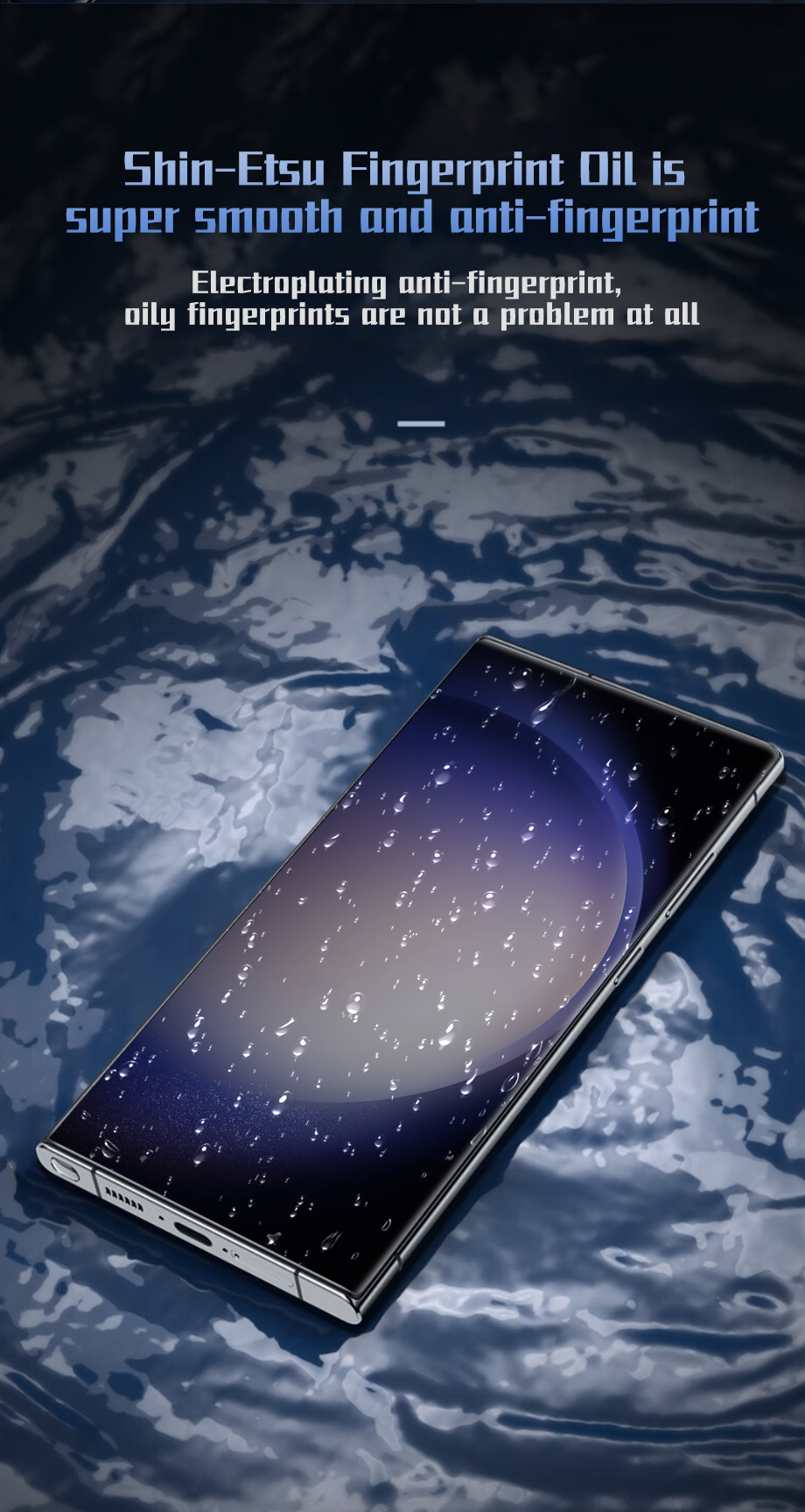

5)Oleophobic coating: anti-fingerprint, anti-soiling, easy to clean.

6) explosion-proof technology: full-screen explosion-proof will not splash broken glass to ensure safety.

2. Production process

Mold: plastic plate knife mold

Principle: Use special chemical solution to repair the extension micro-cracks on the glass end face caused by CNC cutting, so that the cracks will shrink or even disappear to enhance the anti-mechanical ability of the product.

Required equipment: Reclaimer, CNC fine engraving equipment, two-strength bubbling machine, polishing machine, flat grinding equipment, ultrasonic cleaning machine, tempering furnace, plasma spraying equipment, precision laminating equipment

Process flow: open material (1min) → CNC (3min) → cleaning (40min) → two strong (10min) → sweeping (6min) → cleaning (40min) → tempering (6H) → cleaning (40min) → spraying AF (1H) → laminating (1min) → inspection (1min) → labeling (1min) → packaging (2min) → storage

OEM/ODM orders are welcome

Descriptions:

o Material: tempered glass from Japan

o Fit for the curved edge

o 0.33mm thickness body with precise cutting

o Sample cost: free charge, in stock

o Right angle/arc edge, fashionable and beautiful

o Hardness: 9H, super transparency

o Anti-oil, easy absorption

o Pure touch sensitivity

o Hardness: 9H, extremely scratches, wearing and shock-resistant

o Rounded borders, smooth edges

o Easy to wipe and clean, face is smooth

o Repeatable use, no residue, no bubble

o Exquisite crack when it is broken and won't hurt people

| NO. | Item | Unit | Result |

|---|---|---|---|

| 1 | Base film thickness | Mm | 0.4±0.01 |

| 2 | Total thickness | Mm | 0.59±0.02 |

| 3 | Water drop angle test parameters | ° | 105°~118° |

| 4 | Adhesion(G/50MM) | G | 12.8~14.6 |

| 5 | Pencil hardness test | H | 9H |

| 6 | Transparency test | % | 91%-92% |

| 7 | Rainbow stripe | - | Pass |

Product features

1、Using high alumina glass material of Southern Glass, the impact resistance and scratch resistance of the product are guaranteed;

2, high aluminum glass, impact resistance is greatly provided, doubled on the basis of the original (medium aluminum) (64g steel ball, 60cm height, center point free fall 3 times, the product is not broken);

3, anti-fingerprint treatment, can be anti-soiling, easy to clean (surface water drop angle up to 115 degrees or more)

4, the surface hardness of up to 9H, can effectively anti-scratch, explosion-proof screen;

5, full-screen explosion-proof will not splash broken glass to ensure safety;

6, smooth exhaust, a sticker to the end, no residual glue, no white edge.

1. Features

1) Type: iPhone series half screen transparent tempered film;

2) Product technology: tempering;

3) Material: South glass high aluminum + 0.33mm AB adhesive.

4) Pencil hardness: 9H, can effectively resist scratching.

5)Oleophobic coating: anti-fingerprint, anti-soiling, easy to clean.

6) explosion-proof technology: full-screen explosion-proof will not splash broken glass to ensure safety.

2. Production process

Mold: plastic plate knife mold

Principle: Use special chemical solution to repair the extension micro-cracks on the glass end face caused by CNC cutting, so that the cracks will shrink or even disappear to enhance the anti-mechanical ability of the product.

Required equipment: Reclaimer, CNC fine engraving equipment, two-strength bubbling machine, polishing machine, flat grinding equipment, ultrasonic cleaning machine, tempering furnace, plasma spraying equipment, precision laminating equipment

Process flow: open material (1min) → CNC (3min) → cleaning (40min) → two strong (10min) → sweeping (6min) → cleaning (40min) → tempering (6H) → cleaning (40min) → spraying AF (1H) → laminating (1min) → inspection (1min) → labeling (1min) → packaging (2min) → storage

OEM/ODM orders are welcome

Descriptions:

o Material: tempered glass from Japan

o Fit for the curved edge

o 0.33mm thickness body with precise cutting

o Sample cost: free charge, in stock

o Right angle/arc edge, fashionable and beautiful

o Hardness: 9H, super transparency

o Anti-oil, easy absorption

o Pure touch sensitivity

o Hardness: 9H, extremely scratches, wearing and shock-resistant

o Rounded borders, smooth edges

o Easy to wipe and clean, face is smooth

o Repeatable use, no residue, no bubble

o Exquisite crack when it is broken and won't hurt people

| NO. | Item | Unit | Result |

|---|---|---|---|

| 1 | Base film thickness | Mm | 0.4±0.01 |

| 2 | Total thickness | Mm | 0.59±0.02 |

| 3 | Water drop angle test parameters | ° | 105°~118° |

| 4 | Adhesion(G/50MM) | G | 12.8~14.6 |

| 5 | Pencil hardness test | H | 9H |

| 6 | Transparency test | % | 91%-92% |

| 7 | Rainbow stripe | - | Pass |

Product features

1、Using high alumina glass material of Southern Glass, the impact resistance and scratch resistance of the product are guaranteed;

2, high aluminum glass, impact resistance is greatly provided, doubled on the basis of the original (medium aluminum) (64g steel ball, 60cm height, center point free fall 3 times, the product is not broken);

3, anti-fingerprint treatment, can be anti-soiling, easy to clean (surface water drop angle up to 115 degrees or more)

4, the surface hardness of up to 9H, can effectively anti-scratch, explosion-proof screen;

5, full-screen explosion-proof will not splash broken glass to ensure safety;

6, smooth exhaust, a sticker to the end, no residual glue, no white edge.